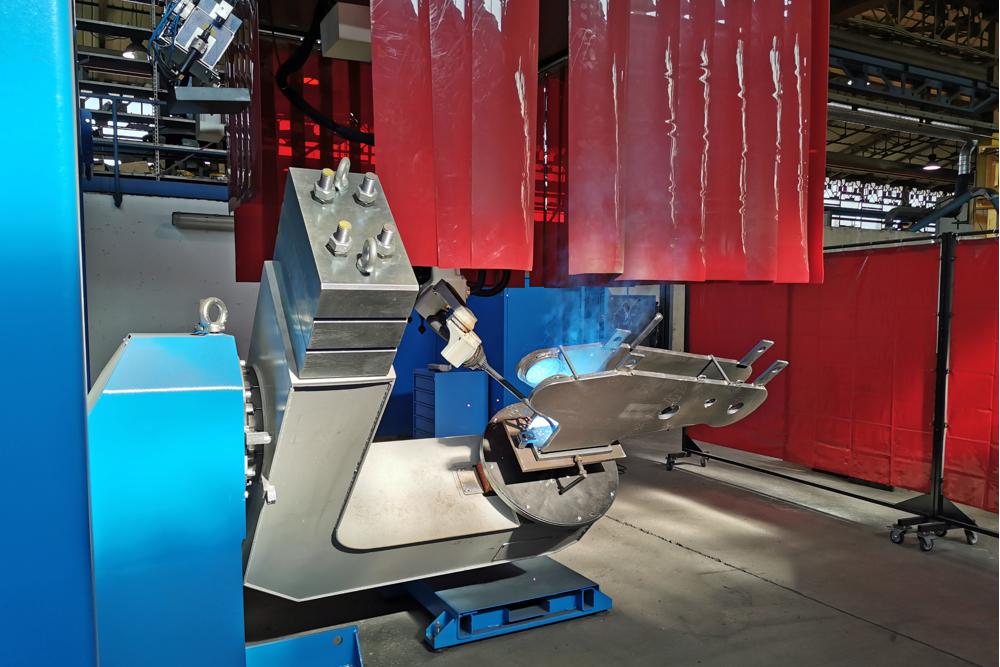

Robotic welding system

Quality and precision guaranteed by robotic welding

Carpenterie Romor owns a robotic welding system with a robot on track equipped with an orbital positioner, load capacity 1000 kg, with tailstock to work with lathe configuration, load capacity 2000 kg, distance between dishes up to 4000 mm, rotating table diameter 2000 mm.

Keeping up to date on innovation is one of our main goals.

For this reason, our robotic welding is based on equipment of great technological value which can carry out both arc welding and spot welding.

The robotic welding cell guarantees not only high welding quality thanks to an accurate and homogeneous movement and reduced cycle time thanks to the high speed of the axes, but also constant welding quality with high standards and a good productivity even for small orders.

The production cycle automation, with fast and high precision preparation of the pieces to be welded and processing completion, allows us to guarantee an excellent service for third parties too, dealing not only with welding and the design and construction of templates for the clamping of pieces, but also, if necessary, with the assembly of metalwork items.

All of which without neglecting a crucial analysis of the type of processing required: although robotic welding guarantees speed of execution, reduction of waste and reworking, automated welding systems are sophisticated and the programming of each processing is demanding. Therefore, it is necessary to carefully evaluate parameters such as the quantity of pieces to be manufactured and the type of welding to be carried out in order to decide whether the savings in terms of time and materials are compatible with the necessary financial commitment.